Products

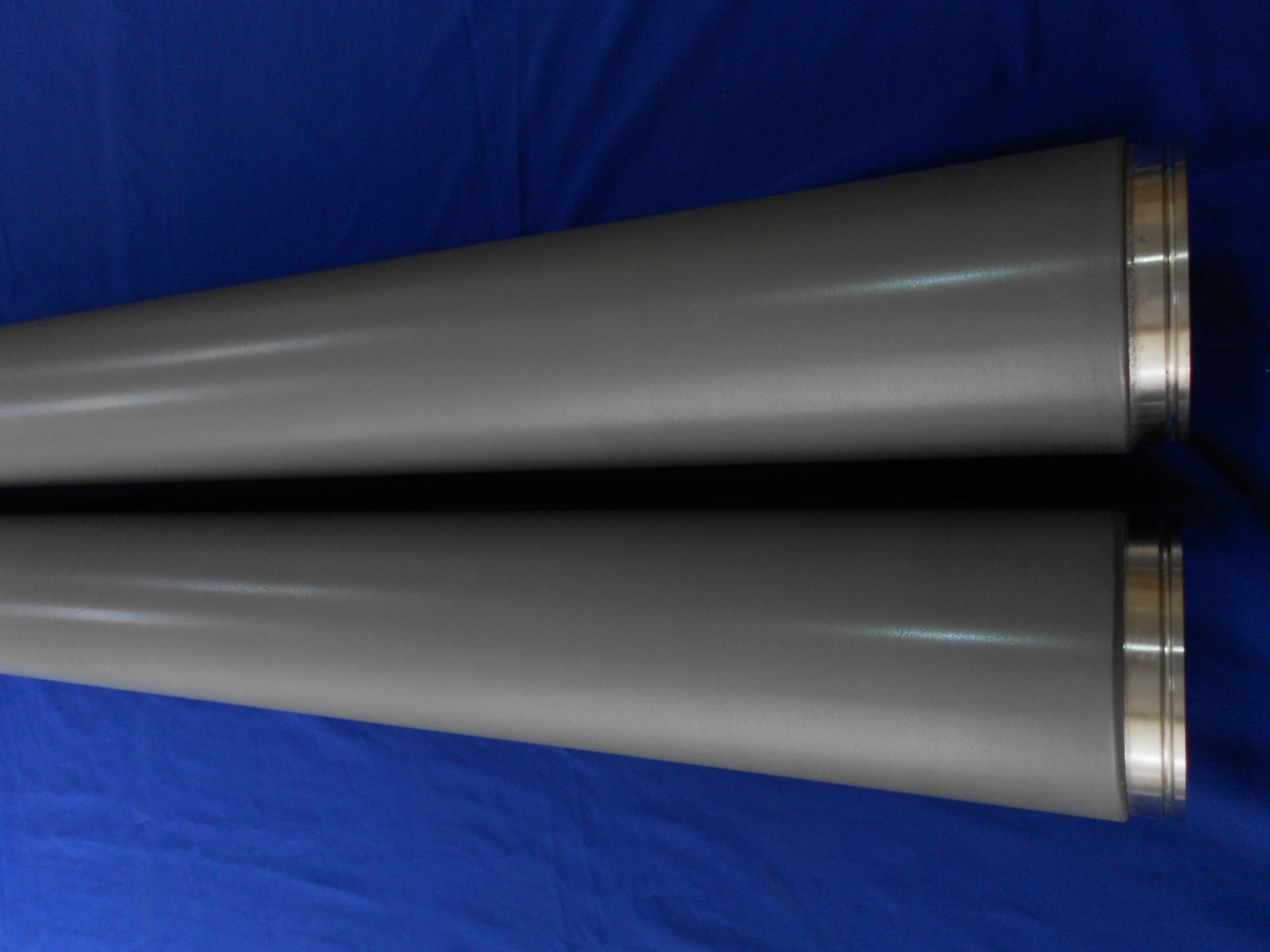

Sputtering Target Division

Our engineering staffs offer more experiences in adapting manufacturing processes to the resolution of problems than perhaps any other institutions in the community. For example, KTX Material processes can apply and manipulate materials to feature specific qualities, such as purity, density, grain size, electrical, dielectric, thermal conductivity....etc., There can be included ceramics, metals and cermets.

Our cooperative approach to innovative engineering sets us apart from our competitors. Providing consultation in order to help define the requirement of an industry and applications. Confidentiality is maintained as our staffs work closely with clients.